CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry by offering precision, efficiency, and flexibility in producing complex components. As technology advances, it is crucial to stay updated on the current status and technical trends of the CNC machining industry. In this post, let’s have a look at the current state of the industry and delve into the emerging technical trends shaping its future.

Current Status of CNC Machining Industry

- Growth in Demand: The CNC machining industry has witnessed significant growth in recent years, driven by the increasing demand for precision-engineered components in various sectors such as automotive, aerospace, defense, and healthcare.

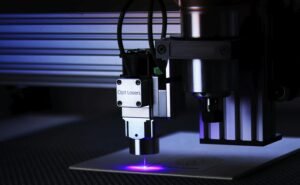

- Advancements in Machine Tools: CNC machine tools have evolved significantly, offering higher accuracy, faster machining speeds, and improved automation capabilities. The industry now utilizes advanced machines equipped with multi-axis functionality, allowing for complex geometries and intricate designs.

- Integration of Automation: Automation has become a key driver in the CNC machining industry. Robotic automation, automated material handling systems, and machine learning algorithms are increasingly being integrated into CNC machining processes, reducing human error and enhancing productivity.

Technical Trends in CNC Machining Industry

- Smart Manufacturing: The adoption of smart manufacturing technologies, enabled by the Internet of Things (IoT), is gaining momentum in the CNC machining industry. These technologies facilitate real-time monitoring, predictive maintenance, and data-driven decision-making, leading to improved efficiency and reduced downtime.

- Additive Manufacturing: While CNC machining involves subtractive processes, the integration of additive manufacturing techniques, such as 3D printing, is becoming prevalent. This combination allows for hybrid manufacturing, where complex components can be produced by adding material and then finish-machined for precision.

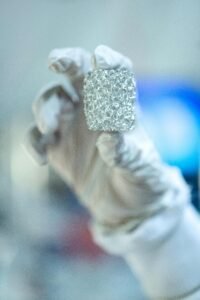

- Advanced Materials: CNC machining is no longer limited to traditional metals; it now encompasses advanced materials like composites, ceramics, and superalloys. These materials offer superior properties, enabling the production of lightweight, high-strength, and corrosion-resistant components.

- Artificial Intelligence and Machine Learning: AI and machine learning algorithms are increasingly being utilized in CNC machining processes for optimization and process improvement. These technologies can analyze vast amounts of data generated during machining to optimize cutting parameters, predict tool wear, and enhance overall efficiency.

Thus, the CNC machining industry is experiencing significant growth, driven by the increasing demand for precision components and advancements in technology. The integration of automation, smart manufacturing, additive manufacturing, advanced materials, and AI is shaping the industry’s future. Staying abreast of these technical trends is essential for businesses to remain competitive and meet the evolving demands of the manufacturing sector.